Revolutionising NHS Laundry Processes: A Sustainable and Cost-Efficient Solution

The unsung aspect of the NHS's operations, textile laundering, surprisingly contributes significantly to environmental pollution. European and UK healthcare sectors cumulatively account for an astonishing 550M KG of CO2e annually1. The resource-intensive laundry processes often involve machines operating at temperatures between 80℃-180℃, leading to unavoidable textile wear and tear. However, the issues don't end there.

Most commercial laundry services avoid stain pre-treatment, given the added labour costs. Instead, they opt for harsh chemicals like optical brighteners and bleach, known for their detrimental effects on aquatic life2. Furthermore, many use dry chemicals such as perc, linked to cancer and miscarriages, thus putting both laundry workers and NHS staff at risk3. Poorly removable stains and inefficient laundering logistics compound the issue, resulting in high wastage within the NHS textile supply chain. This inefficiency translates into an astounding annual loss of millions of taxpayer money.

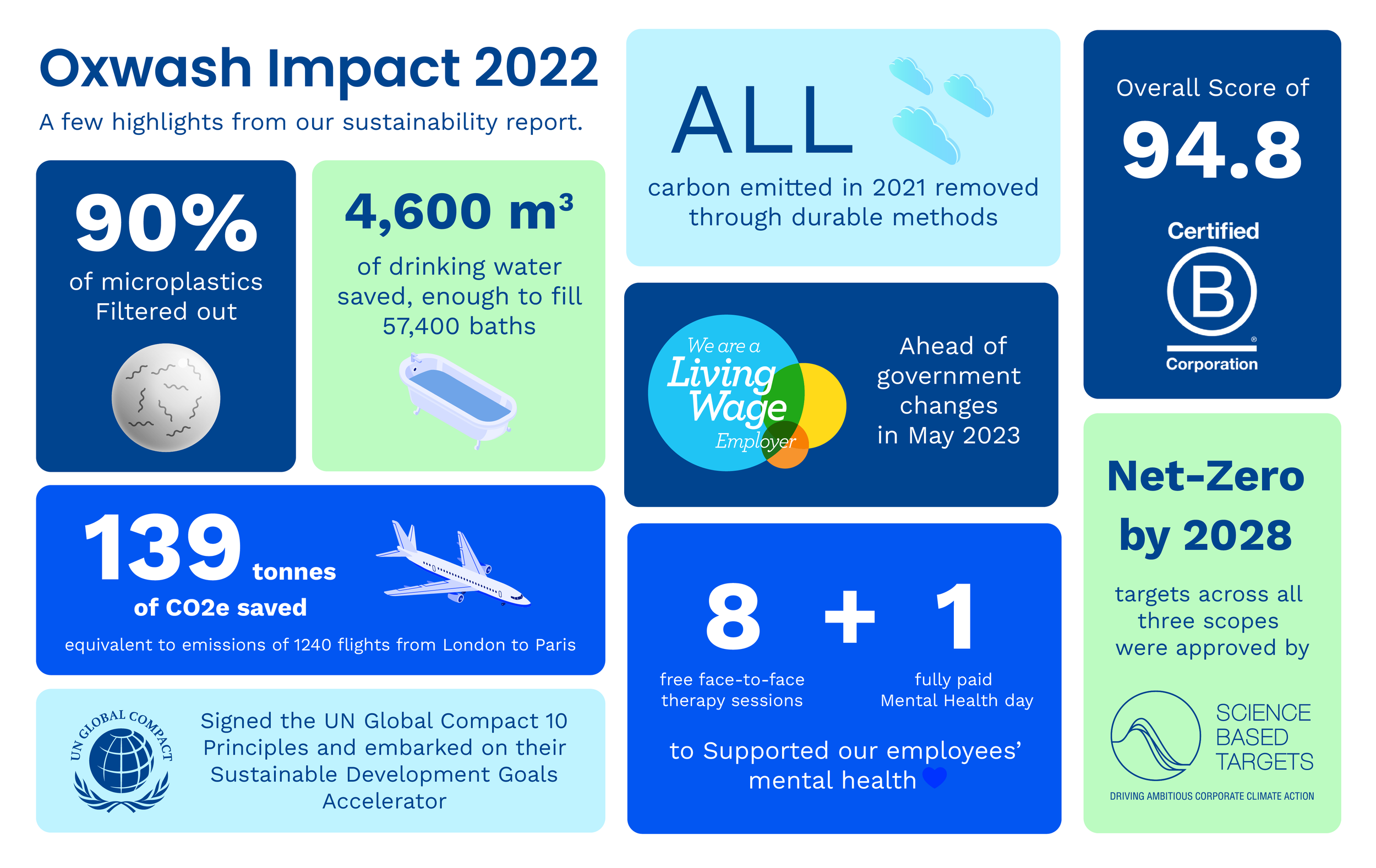

In the face of this pressing issue, we at Oxwash, the world's first B Corp™ certified, carbon-neutral laundry service, are on a mission to prolong the life of textiles for healthier people and a cleaner planet. Our founder, Dr. Kyle Grant, a former NASA engineer, firmly believes that resource efficiency is the pathway to both sustainability and cost reduction. This ethos underpins our successful efforts to drastically reduce emissions, water consumption, and toxicity, all the while maintaining high service standards and prioritising our employees' welfare.

Reducing Emissions and Water Impacts

At Oxwash, we use proprietary technology that dramatically reduces energy usage by more than half compared to traditional laundries4. We use ozone supersaturation to eradicate over 99.99% of germs at lower temperatures with biodegradable detergents, achieving log7 disinfection5. We also recycle over 60% of our water and filter 99% of our microfibers to avoid water pollution. Our science-based net-zero targets guide us towards our ambitious goal: to decarbonise commercial laundry by 2028, driving our R&D initiatives such as our low-energy ultrasonic drying technology.

Automation and Real-Time Traceability

To prevent stock loss, our data team is designing a customer-centric bespoke system that will provide a birds eye view of stock in real time. Our cutting-edge software, AI and tagging technology will enable customers to easily manage orders, trace items, and optimise routing.

People Wellbeing

Our people are our greatest strength. We foster a healthy and safe working environment, ensuring a Living Wage, free mental health support and regular training. This allows us to maintain a high NPS employer score and retain our valuable staff, translating into an overall boost in productivity per employee and superior quality.

Conclusion: Laundry aligned with Greener NHS.

Embracing a resource-efficient commercial laundry strategy is a pivotal step towards realising the ambitions of a Greener NHS. By consuming less energy and water, we can make considerable strides in diminishing Scope 3 emissions, driving closer to the Net-Zero ambition. But the transformation doesn't stop there. By integrating automation and fostering a highly productive workforce, we can greatly minimise stock loss, dramatically reducing textile waste. This is not a small win – it signifies a potential annual saving of millions of pounds, turning a day-to-day operational process into a powerful catalyst for sustainable change, one laundry load at a time.

Contact us today to explore the full range of services and discover why Oxwash is the preferred choice for businesses seeking a transformative laundry experience.

References:

1 TKT, 2019; Oxwash’s Report, 2022.

2 European Chemicals Bureau, 2007.

3 Environmental Protection Agency, 2012.

4 Carbon Trust (2009) reports that small commercial laundries and on-premises laundries processing fewer than 100 000 pieces per week consume 2.0 to 2.9 kWh per kg textiles (total consumption, including for non-laundry processes such as lighting).

5 CCD and Oxwash, 2022.